|

|

| |

|

|

Application: |

All high-density boards |

| Product Features: |

2920 Dimension, Surface mountable, Solid state, Faster

time to trip than standard SMD devices. |

| Operation Current: |

300mA~3.0A |

|

| Maximum Voltage: |

6V~60V |

| Temperature Range: |

-40°C to 85°C |

| Agency Recognition: |

UL C-UL TÜV Pending |

|

| |

|

|

| |

Part

Number |

Hold

Current |

Trip

Current |

Rated

Voltage

|

Maximum

Current

|

Typical

Power

|

Max Time to Trip |

Resistance Tolerance |

| RMIN |

R1MAX |

| IH, A |

IT, A |

VMAX,Vdc |

IMAX, A |

Pd, W |

Current |

Time |

ohms |

ohms |

| FSMD030-2920 |

0.30 |

0.6 |

60 |

10 |

1.5 |

1.5 |

3.0 |

1.20 |

4.80 |

| FSMD050-2920 |

0.60 |

1.0 |

60 |

10 |

1.5 |

2.5 |

4.0 |

0.35 |

1.40 |

| FSMD075-2920 |

0.75 |

1.5 |

33 |

40 |

1.5 |

8.0 |

0.3 |

0.35 |

1.00 |

| FSMD100-2920 |

1.10 |

2.2 |

33 |

40 |

1.5 |

8.0 |

0.5 |

0.12 |

0.41 |

| FSMD125-2920 |

1.25 |

2.5 |

33 |

40 |

1.5 |

8.0 |

2.0 |

0.07 |

0.25 |

| FSMD150-2920 |

1.50 |

3.0 |

33 |

40 |

1.5 |

8.0 |

2.0 |

0.06 |

0.23 |

| FSMD185-2920 |

1.85 |

3.7 |

33 |

40 |

1.5 |

8.0 |

2.5 |

0.06 |

0.15 |

| FSMD200-2920 |

2.00 |

4.0 |

16 |

40 |

1.5 |

8.0 |

4.5 |

0.05 |

0.12 |

| FSMD250-2920 |

2.50 |

5.0 |

16 |

40 |

1.5 |

8.0 |

16 |

0.035 |

0.085 |

| FSMD260-2920 |

2.60 |

5.2 |

6 |

40 |

1.5 |

8.0 |

20 |

0.025 |

0.075 |

| FSMD300-2920 |

3.00 |

6.0 |

6 |

40 |

1.5 |

8.0 |

25 |

0.015 |

0.048 | |

| |

IH=Hold current-maximum current at which the

device will not trip at 23°C still air.

IT=Trip

current-minimum current at which the device will always trip at 23°C still

air.

V MAX=Maximum voltage device can withstand

without damage at its rated current.

I MAX=

Maximum fault current device can withstand without damage at rated voltage

(V max).

Pd=Typical power dissipated from device

when in the tripped state in 23°C still air environment.

RMIN=Minimum device resistance at 23°C.

R1MAX=Maximum device resistance at 23°C, 1 hour after

tripping .

Termination pad characteristics

Termination pad

materials: solder-plated copper

|

| |

|

|

|

|

Part

Number |

A |

B |

C |

D |

|

Min |

Max |

Min |

Max |

Min |

Max |

Min |

| FSMD030-2920 |

6.73 |

7.98 |

4.80 |

5.44 |

0.60 |

1.15 |

0.35 |

| FSMD050-2920 |

6.73 |

7.98 |

4.80 |

5.44 |

0.60 |

1.15 |

0.35 |

| FSMD075-2920 |

6.73 |

7.98 |

4.80 |

5.44 |

0.60 |

1.15 |

0.35 |

| FSMD100-2920 |

6.73 |

7.98 |

4.80 |

5.44 |

0.40 |

1.00 |

0.35 |

| FSMD125-2920 |

6.73 |

7.98 |

4.80 |

5.44 |

0.40 |

0.90 |

0.35 |

| FSMD150-2920 |

6.73 |

7.98 |

4.80 |

5.44 |

0.40 |

0.90 |

0.35 |

| FSMD185-2920 |

6.73 |

7.98 |

4.80 |

5.44 |

0.30 |

0.90 |

0.35 |

| FSMD200-2920 |

6.73 |

7.98 |

4.80 |

5.44 |

0.30 |

0.90 |

0.35 |

| FSMD250-2920 |

6.73 |

7.98 |

4.80 |

5.44 |

0.30 |

0.90 |

0.35 |

| FSMD260-2920 |

6.73 |

7.98 |

4.80 |

5.44 |

0.30 |

0.90 |

0.35 |

| FSMD300-2920 |

6.73 |

7.98 |

4.80 |

5.44 |

0.40 |

0.90 |

0.35 |

| |

| |

|

| |

|

| |

|

| |

|

A = FSMD030-2920

B = FSMD050-2920

C =

FSMD075-2920

D = FSMD100-2920

E = FSMD125-2920

F =

FSMD150-2920

G = FSMD185-2920

H = FSMD200-2920

I =

FSMD250-2920

J = FSMD260-2920

K= FSMD300-2920

|

| |

| |

|

| |

|

| |

|

P/N |

Pcs

/Bag |

Reel/Tape |

|

FSMD030-2920 |

----- |

2K |

|

FSMD050-2920 |

----- |

2K |

|

FSMD075-2920 |

----- |

2K |

|

FSMD100-2920 |

----- |

2K |

|

FSMD125-2920 |

----- |

2K |

|

FSMD150-2920 |

----- |

2K | |

|

|

P/N |

Pcs

/Bag |

Reel/Tape |

|

FSMD185-2920 |

----- |

2K |

|

FSMD200-2920 |

----- |

2K |

|

FSMD250-2920 |

----- |

2K |

|

FSMD260-2920 |

----- |

2K |

|

FSMD300-2920 |

----- |

2K |

|

|

| |

| Warning: |

- Operation beyond the specified maximum ratings or improper use

may result in damage and possible electrical arcing and/or flame.

- PPTC device are intended for occasional overcurrent

protection. Application for repeated overcurrent condition and/or

prolonged trip are not anticipated.

- Avoid contact of PPTC device with chemical solvent. Prolonged

contact will damage the device performance.

|

|

|

|

| |

Pad Layouts,

Solder Reflow and Rework Recommendations

The dimension in

the table below provide the recommended pad layout for each FSMD1812

device |

|

| Pad dimensions (millimeters) |

| Device |

A |

B |

C |

| Nominal |

Nominal |

Nominal |

| FSMD030-2920 |

5.10 |

2.30 |

5.60 |

| FSMD050-2920 |

5.10 |

2.30 |

5.60 |

| FSMD075-2920 |

5.10 |

2.30 |

5.60 |

| FSMD100-2920 |

5.10 |

2.30 |

5.60 |

| FSMD125-2920 |

5.10 |

2.30 |

5.60 |

| FSMD150-2920 |

5.10 |

2.30 |

5.60 |

| FSMD185-2920 |

5.10 |

2.30 |

5.60 |

| FSMD200-2920 |

5.10 |

2.30 |

5.60 |

| FSMD250-2920 |

5.10 |

2.30 |

5.60 |

| FSMD260-2920 |

5.10 |

2.30 |

5.60 |

| FSMD300-2920 |

5.10 |

2.30 |

5.60 | |

|

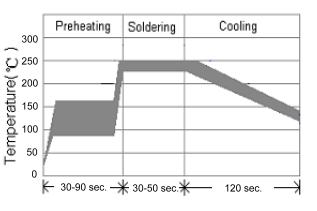

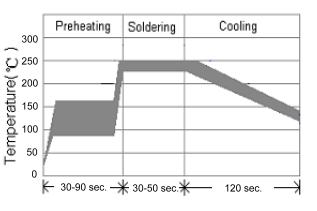

Solder reflow

Due to “Lead Free” nature, up to 40 seconds Dwelling

time for the soldering zone is strongly recommend .

1.

Recommended reflow methods; IR, vapor phase oven, hot air

oven.

2. The FSMD1812 Series are suitable for use with

wave-solder application methods.

3. Recommended maximum paste

thickness is 0.25mm.

4. Devices can be cleaned using standard

industry methods and solvents.

CAUTION:

If reflow

temperatures exceed the recommended Profile, devices may not meet

the performance requirements.

Rework:

Use standard industry

practices.

All the specifications

are subject to change without previous notice.

| |

![]()