![]()

|

Application: | All high-density boards |

| Product Features: | Small surface mount, Solid state Faster time to trip than standard SMD devices Lower resistance than standard SMD devices | |

| Operation Current: | 140mA~1.6A | |

| Maximum Voltage: | 6V~60V | |

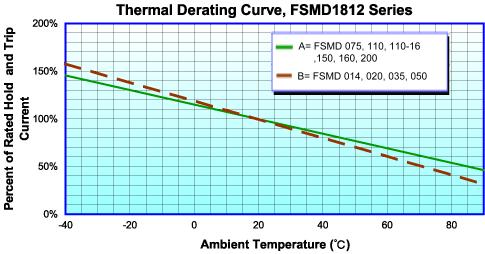

| Temperature Range: | -40°C to 85°C | |

| Agency Recognition: | UL (E211981), TÜV (R50004084) |

|

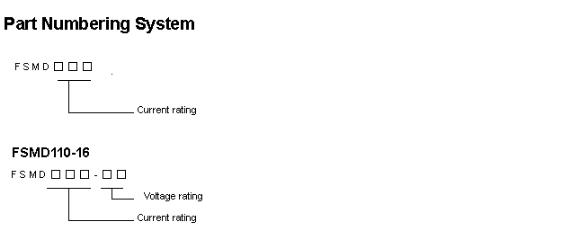

Part Number |

Hold Current |

Trip Current |

Rated Voltage |

Max Current |

Typical Power |

Max Time to Trip |

Resistance Tolerance | ||

|

Current |

Time |

RMIN |

R1MAX | ||||||

|

IH, A |

IT, A |

VMAX, Vdc |

IMAX, A |

Pd, W |

Amp |

Sec |

Ω |

Ω | |

|

FSMD014 |

0.14 |

0.30 |

60 |

10 |

0.8 |

8.0 |

〈0.02 |

1.50 |

6.50 |

|

FSMD020 |

0.20 |

0.40 |

30 |

10 |

0.8 |

8.0 |

0.02 |

0.80 |

5.00 |

|

FSMD035 |

0.35 |

0.70 |

16 |

40 |

0.8 |

8.0 |

0.10 |

0.32 |

1.50 |

|

FSMD050 |

0.50 |

1.00 |

16 |

40 |

0.8 |

|

0.15 |

0.15 |

1.00 |

|

FSMD075 |

0.75 |

1.50 |

16 |

40 |

0.8 |

8.0 |

0.02 |

0.11 |

0.45 |

|

FSMD110 |

1.10 |

2.20 |

6 |

40 |

0.8 |

8.0 |

0.30 |

0.04 |

0.21 |

|

FSMD110-16 |

1.10 |

1.95 |

16 |

40 |

0.8 |

8.0 |

0.50 |

0.04 |

0.18 |

|

FSMD150 |

1.50 |

3.00 |

6 |

40 |

0.8 |

8.0 |

0.50 |

0.04 |

0.11 |

|

FSMD160 |

1.60 |

3.20 |

6 |

40 |

0.8 |

8.0 |

〈0.5 |

0.03 |

0.10 |

|

FSMD200 |

2.00 |

3.50 |

8 |

40 |

0.8 |

8.0 |

2 |

0.02 |

0.07 |

IH=Hold current-maximum current at which the device will not trip at 23℃still air.

IT=Trip current-minimum current at which the device will always trip at 23℃ still air.

V MAX=Maximum voltage device can withstand without damage at it rated current.(I max)

I MAX= Maximum fault current device can withstand without damage at rated voltage (V max).

Pd=Typical power dissipated-type amount of power dissipated by the device when in the tripped state in 23℃ still air environment.

RMIN=Minimum device resistance at 23℃ prior to tripping.

R1MAX=Maximum device resistance at 23℃ measured 1 hour post trip.

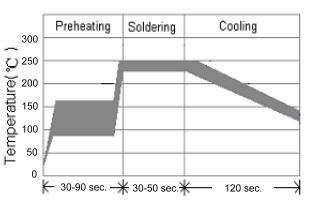

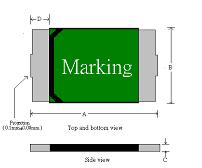

Termination pad characteristics

Termination pad materials: Tin-plated copper

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

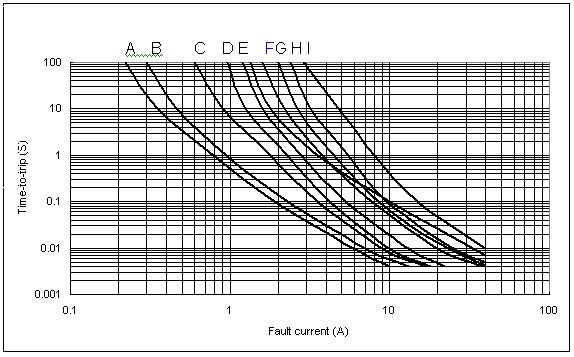

A =FSMD014 B =FSMD020 C =FSMD035 D =FSMD050 E =FSMD075 F =FSMD110-16 G = FSMD110 H =FSMD150 I =FSMD160 J=FSMD200 |

|

![]()

|

| Warning: |

|

|

|