|

Application: | Wide variety of electronic equipment |

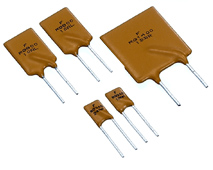

| Product Features: | Very high hold current, Solid state Radial-leaded product ideal for up to 16Vdc | |

| Operation Current: | 3 A~14A | |

| Maximum Voltage: | 16V | |

| Temperature Range: | -40°C to 85°C | |

| Agency Recognition: | UL(E211981),

C-UL(E211981) TÜV(R50004084) |

| Part Number |

Hold Current |

Trip Current |

Max.Time to Trip |

Maximum Current |

Rated Voltage |

Typical Power |

Resistance Tolerance | |

| RMIN | R1MAX | |||||||

| IH, A | IT, A | at 5xIH | IMAX, A | VMAX,Vdc | Pd, W | ohms | ohms | |

| FRG300-16 | 3.0 | 5.1 | 2.0 | 100 | 16 | 2.3 | 0.034 | 0.105 |

| FRG400-16 | 4.0 | 6.8 | 3.5 | 100 | 16 | 2.4 | 0.020 | 0.063 |

| FRG500-16 | 5.0 | 8.5 | 3.6 | 100 | 16 | 2.6 | 0.014 | 0.044 |

| FRG600-16 | 6.0 | 10.2 | 5.8 | 100 | 16 | 2.8 | 0.009 | 0.033 |

| FRG700-16 | 7.0 | 11.9 | 8.0 | 100 | 16 | 3.0 | 0.006 | 0.021 |

| FRG800-16 | 8.0 | 13.6 | 9.0 | 100 | 16 | 3.0 | 0.005 | 0.018 |

| FRG900-16 | 9.0 | 15.3 | 12.0 | 100 | 16 | 3.3 | 0.004 | 0.015 |

| FRG1000-16 | 10.0 | 17.0 | 12.5 | 100 | 16 | 3.3 | 0.003 | 0.012 |

| FRG1100-16 | 11.0 | 18.7 | 13.5 | 100 | 16 | 3.7 | 0.003 | 0.010 |

| FRG1200-16 | 12.0 | 20.4 | 16.0 | 100 | 16 | 4.2 | 0.002 | 0.009 |

| FRG1400-16 | 14.0 | 23.8 | 20.0 | 100 | 16 | 4.6 | 0.002 | 0.008 |

| IH=Hold

current-maximum current at which the device will not trip at 23°C

still air. IT=Trip current-minimum current at which the device will always trip at 23°C still air. V MAX=Maximum voltage device can withstand without damage at its rated current. I MAX= Maximum fault current device can withstand without damage at rated voltage (V max). Pd=Typical power dissipated from device when in the tripped state in 23°C still air environment. RMIN=Minimum device resistance at 23°C. R1MAX=Maximum device resistance at 23°C, 1 hour after tripping . Physical specifications: Lead material: Tin plated copper, 24 AW | |

| Soldering characteristics: | FRG300~FRG1100 Tin plated

copper, 20 AWG. FRG1200~FRG1400 Tin plated copper, 18 AWG. |

| Soldering characteristics: MIL-STD-202,

Method 208E. Insulating coating:Flame retardant epoxy, meet UL-94V-0 requirement. | |

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

A=FRG300-16 |

|

![]()

|

|

| Warning: |

|

|

|

All the specifications are subject to change without previous notice.